Minimum Control Measures For Small Construction Projects

Remember that storm drains and runoff flow directly to our creeks and rivers untreated. Taking minimum control measures for construction projects as noted below helps protect our waterways and their aquatic life.

Select an effective combination of control measures from each category, Erosion Control, Sediment Control, and Good Housekeeping. Control measures shall be continually implemented and maintained throughout the project until activities are complete, disturbed areas are stabilized with permanent erosion controls, and the local agency has signed off on permits that may have been required for the project. Inspect and maintain the control measures before and after rain events, and as required by the local agency or state permit.

Erosion Controls

Source control practices that protect soil and prevent soil particles from being detached by rainfall, flowing water, or wind.

1 – Scheduling: Scheduling allows you to plan activities when there is a lower chance of rain and to plan for BMP installation as the activities progress.

2 – Preserve Vegetation & Creek Set Backs: Existing vegetation is the best form of erosion control, doesn’t cost money to install, and requires little maintenance. Preserving vegetation between the site and creeks is especially important and required in some situations.

3 – Soil Cover: Soil cover products, like hydromulch, replace the erosion control benefit of vegetation removed during construction. These products can be quickly deployed over large (or small) disturbed areas for temporary protection and can be incorporated into final stabilization.

4 – Soil Preparation/Roughening: This practice prepares the soil for growing vegetation. Mechanically roughening the soil slows the water down and provides pockets that promote germination. Soil prep also includes testing the soil to identify if any amendments are needed to promote growth.

5 – Erosion Control Blankets: Soil cover products, like erosion control blankets, replace the erosion control benefit of vegetation removed during construction. These products are used for temporary projection and can be incorporated into final stabilization.

6 – Revegetation: Revegetation re-establishes vegetation on the areas of the site disturbed by construction to prevent erosion. It is part of the final stabilization of the site but may also be needed for temporary protection during the project.

Sediment Controls

Practices that trap soil particles (sediment) after they have been detached by rainfall, flowing water, or wind.

7 – Tracking Controls: Tracking controls are a suite of practices that limit the amount of dirt and mud tracked from a project into the street. Keeping dirt out of the street helps to keep it out of the storm drains and reduces complaints from neighbors.

8 – Fiber Rolls: Fiber rolls intercept runoff, reduce its velocity, and trap sediment behind the roll. They also reduce the length of a slope, which reduces sheet and rill erosion.

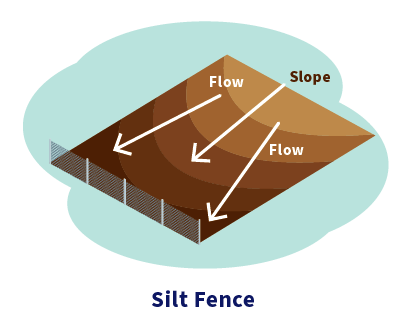

9 – Silt Fence: Silt fences detain (pond) water promoting sedimentation behind the fence.

10 – Drain Inlet Protection: Drain Inlet Protection (DI) is used as a last line of defense. It temporarily ponds water at the drain inlet, allowing some sediment to settle out. Some forms of DI protection can filter sediment during low flow events.

Good Housekeeping

Practices that prevent pollution by limiting the exposure of construction materials with rain, flowing water, or wind. These practices involve keeping a clean and orderly construction site.

11 – Concrete Washout: These practices prevent the discharge of high pH concrete wastewater into the ground or storm drains.

12 – Stockpile Management: These practices and procedures protect loose stockpiled materials from washing or blowing off the projects site.

13 – Hazardous Material Management: These practices prevent the discharge of hazardous materials by using proper storage of materials and wastes, and by minimizing the quantity of materials stored.

14 – Sanitary Waste Management: Proper management of sanitary waste facilities, e.g., portable toilets, prevents the discharge of wastewater to the ground and storm drains.

15 – Equipment and Vehicle Maintenance: These practices prevent discharges of vehicle fluids and wastes by limiting on-site maintenance and using practices a to contain and clean up small leaks and drips.

16 – Litter and Waste Management: These practices prevent the discharge of trash and wastes from the project site by using covered and contained trash cans and bins.